As of June 2023, Vale Brazil, the worldwide biggest iron ore producer, has approved the SpectraFlow Crossbelt Analyzer for online measurement of iron ore material at its ports and mines. After a rigorous trial that tested the stability of the hardware and measurement accuracy of the analyzer, SpectraFlow Analytics is now the chosen provider for Vale’s online iron ore analysis.

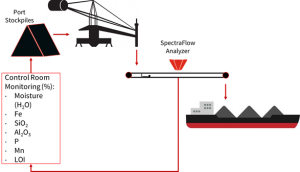

Vale’s Guaíba Island Terminal (TIG) is a port that receives raw material from a large number of variable iron ore sources by train and loads the material onto ships for export. Global demand, local supply and heightening climate change and sustainability pressures necessitate stricter quality assurance and control measures from the world’s largest iron ore producer. Also, as one of the largest logistics operators in Brazil, Vale has impetus to manage train and ship loading schedules with ever smaller margins for delay. Online analysis has the potential to address all these stresses through real time chemical and mineral analysis. SpectraFlow’s Online Near Infrared technology, has enabled Vale to realize this potential.

Minute by minute measurements for iron and other key chemical constituents by a successfully installed Crossbelt Analyzer were compared with sample measurements by Vale’s laboratory. Accurate moisture analysis is of particularly high importance at TIG, as there is risk of ship capsizing if the material moisture levels are not strictly controlled. Fortunately for Vale, SpectraFlow’s Online measurements of moisture and all other critical chemical constituents were found to be well within the strict delta limits set by Vale’s quality control protocol. In fact the analyzer’s measurements have already been used to eliminate unplanned stoppages at TIG, helping Vale reduce downtime and deliver value timeously. Now that the technology is proven, the SpectraFlow analyzer can also be used to blend material to reach optimum grade and gangue targets at the port and even sooner in the value chain, at Vale’s mines

.

SpectraFlow Installation for Advanced Process Control (APC):

The SpectraFlow analyzer is an online analyzer that measures dry raw material composition at key points in mining, processing and refining value chains. Usually placed over a conveyor belt, or in an airslide, the analyzer is able to measure fine deviations in the moisture, grade or gangue composition of the material in real time. By using the measurements from the analyzer that are exchanged directly with the control room PLC or from SpectraFlow’s database and monitoring user interface, bulk mineral, precious metal and cement producers can create automated control loops for quality control and assurance of their final product.

The summarized benefits of SpectraFlow’s online NIR analyzer are:

- The analyzer is free of any radioactive sources, neutron generators or any hazardous components. This means the SpectraFlow analyzer does not require any permits or licenses regarding importation, operation or maintenance. This also means that the SpectraFlow analyzer is completely safe, maintenance can be done by the plant personal.

- Real time, short acquisition time measurements of the complete flow of material gives the customer the opportunity to provide high resolution feed forward information to downstream processing or make value-based ore sorting control decisions on the material.

- The Crossbelt Analyzer reduces the need for frequent belt cuts or manual sampling of the material for quality control, and instead gives the user the user large amounts of accurate composition data for real time feedback on upstream quality delivery like ore block control and stockpile blending.

SpectraFlow has installed more than 75 analyzers in 28 countries worldwide. SpectraFlow Analytics Ltd. Switzerland are thus experts in providing onliDear Beatrice Ene,ne analysis for the iron ore, cement, bauxite, gold, platinum, copper, potash, phosphate, coal and other minerals industries.

Meet SpectraFlow Analytics at CarbonZero Global Conference and Exhibition 2023 in Lyon, France – email contact@industrylink.eu for details on program and pricing for the event.